Background

Autonomous mobile robots (AMR) are transforming industry by automating internal transportation and material handling tasks, bringing a new level of efficiency, flexibility and cost effectiveness to modern operations. Companies are under increasing pressure to optimize workflows and reduce downtime. AMRs offer a dynamic solution by autonomously navigating complex environments, adapting to changes in real time and performing tasks without human intervention.

One of the leading innovators in this industry is MiR, a manufacturer of mobile industrial robots. MiR's robots are designed to integrate seamlessly into a variety of industries, from manufacturing to warehousing to healthcare, where they optimize material flow and increase productivity. With their ability to work safely alongside human workers and handle a range of payloads, they set a new standard for automated logistics solutions.

A key element to the high performance and precision of these AMRs is the integration of advanced technologies, such as magnetic encoders. They provide important position feedback that improves the robots' navigation and operational accuracy, ensuring reliable and efficient performance in complex environments.

Challenge

MiR specializes in the development and manufacture of autonomous mobile robots. Their robots, such as MiR250, MiR600 and MiR1350, can tow carts, lift and transport shelves or pallets and handle heavy loads of up to 1350 kg. Their solutions are flexible, safe and easy to implement and increase operational efficiency and productivity.

When designing and building AMRs, several critical factors and challenges must be taken into account. One important aspect is ensuring precise and reliable navigation and localization, which is achieved through the use of technologies such as LIDAR, cameras and sensors.

Another important aspect is safety, which involves implementing robust systems to detect and avoid obstacles and ensure safe interaction with people and machines. Battery life and efficiency are also of great importance and require the development of power management systems that maximize operational time and minimize downtime for recharging.

Balancing these advanced features with cost efficiency is critical to making AMRs a worthwhile investment for businesses. Considering these factors is important to meet the demands of modern industrial and commercial environments.

Solution

AMRs require precise position information in order to navigate efficiently and avoid obstacles. RLS encoders such as the redundant incremental RoLin encoders and OnAxis encoders are suitable for this application as they provide feedback on wheel rotation to ensure accurate motion control.

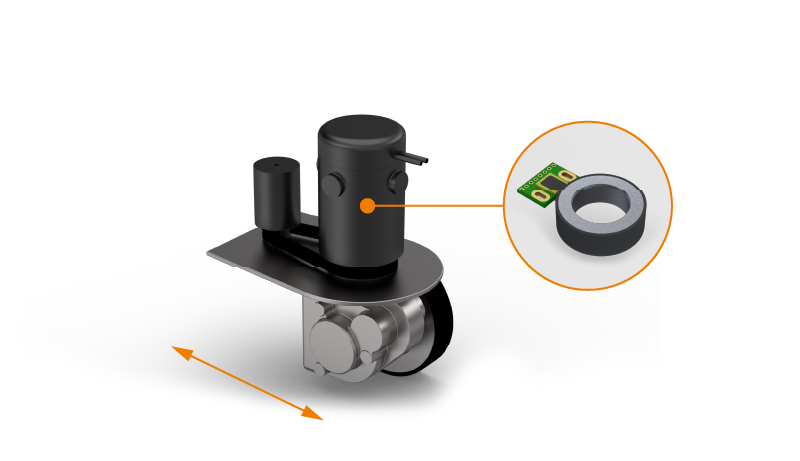

The RoLin system consists of a incremental readhead and a radial ring, making it suitable for both linear and rotary motion sensing. These compact PCB-level magnetic encoders deliver a system accuracy of ±0.3° and have an analog sin/cos output of 2.5 V ±0.5 V. With a resolution of up to 13 bits and an operating temperature range of −20 °C to +105 °C, they perform reliably in harsh industrial environments. The RoLin product line includes versatile options like the RLC2IC, RLC2HD, RLM and RLB, ensuring a wide range of solutions for different application needs.

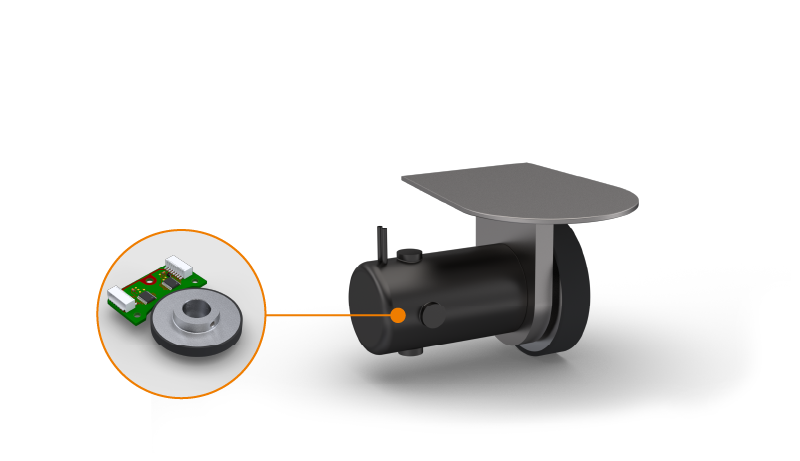

Another encoder frequently integrated into AMRs is the RM44 redundant magnetic encoder, which is suitable for mounting on electric motors or other devices for measuring shaft position and speed. Its robust solid metal housing offers the highest IP protection classes, high EMC immunity, an extended operating temperature range and the best possible resistance to shock and vibration resistance. The output signals are provided in industry standard absolute, incremental, analogue, sinusoidal and linear voltage formats, ensuring compatibility with various applications.

Drive control on AMR

Steering on AMR

Both RoLin and OnAxis systems can be designed in redundant versions, providing a higher level of safety. This feature ensures continuous operation even in the event of a failure, a critical requirement for safety-related AMR tasks that are often performed in close proximity to people.

Results

The precision of RLS encoders plays a key role in enabling accurate navigation, allowing the robot to follow predefined paths and avoid obstacles with high accuracy. It also supports localization by providing important data to determine the exact position of the robot. RLS encoders increase safety by ensuring smooth and controlled movements of the robot, preventing collisions and improving overall operational safety.

One of the most important advantages of RLS encoders is their durability. They are designed for use in demanding environments and are highly resistant to dust, dirt and other contaminants. Their compact design not only ensures high performance, but also allows easy integration into tight spaces, minimizing space requirements. In addition, these encoders are reliable even under harsh conditions, such as extreme temperature fluctuations and vibrations. Magnetic encoders also require less maintenance compared to other types, resulting in less downtime and lower maintenance costs.

MiR chose to work with RLS due to aligned goals between companies. RLS, as a leading manufacturer of magnetic encoders, has extensive experience and innovative approaches, ensuring high quality products that meet MiR's demanding requirements. RLS is also known for offering customized product solutions that can be tailored to specific applications. This flexibility is beneficial to MiR as it enables the integration of highly specialized encoders that fit perfectly into the design and operational requirements of their AMRs.

Future goals

MiR strives to become a one-stop shop for internal logistics and material handling, continuously developing the right solutions and services to meet evolving customer needs. With a strong focus on advanced robotics and artificial intelligence, MiR aims to enhance the capabilities of its AMRs to provide even greater efficiency, flexibility and safety, making them a key asset in industries such as manufacturing, automotive and healthcare.

About MiR

MiR is a Danish pioneer in the field of collaborative, autonomous mobile robots that are changing the way companies handle their internal logistics.

For more information about MiR visit: mobile-industrial-robots.com